Über Uns

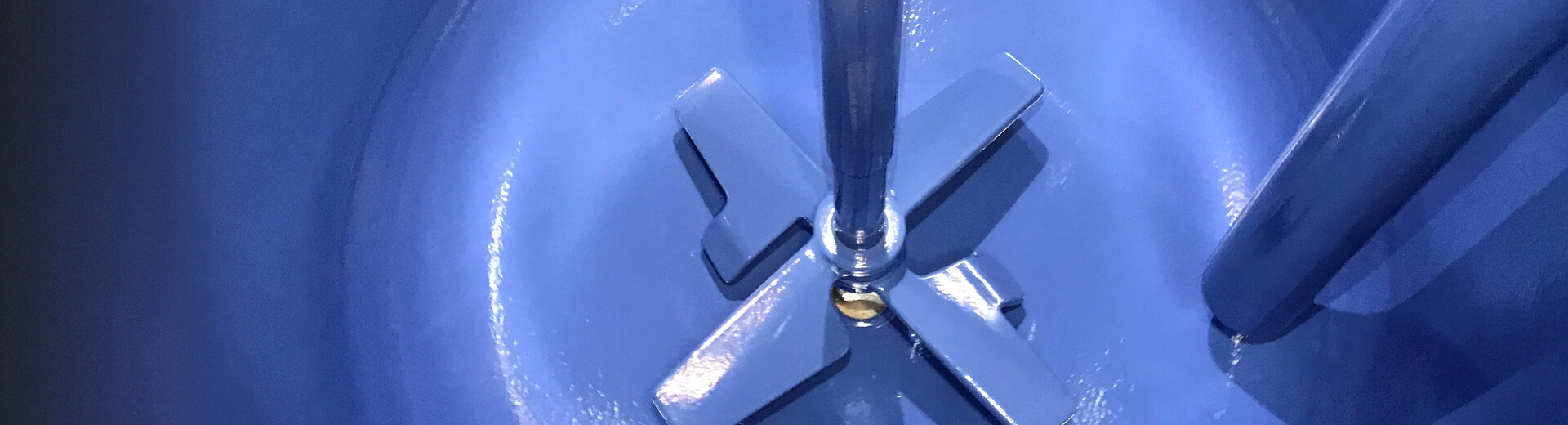

Von THALETEC erhalten Sie das gesamte Spektrum emaillierter Apparate: seien es Tanks, Kolonnen oder Vorlagen. Alternativ auch hocheffiziente Rührwerksapparate mit Doppelmantel oder Halbrohrschlangen. Ebenso unsere besonders effizienten emaillierten Kompaktwärmetauscher oder solche mit SIC-Rohren für eine noch kompaktere Bauweise. Oder Ersatzteile, die für eine hohe Verfügbarkeit Ihrer Anlagen unerlässlich sind.

Für Anwendungen in der Energie-, Umwelt- und Kraftwerkstechnik bietet THALETEC emaillierte Wärmetauscherrohre bis zu 12.000 mm Länge an, die weltweit einzigartig sind und in einer voll automatisierten, kontinuierlich arbeitenden Anlage in höchster Qualität hergestellt werden.

All unsere Produkte sind „Made in Germany“. Hergestellt aus Komponenten und Materialien zertifizierter, zumeist deutscher Qualitätslieferanten, bieten wir ein umfassendes Programm hochwertiger und zuverlässiger Apparate, ob standardisiert oder ganz individuell nach Kundenwunsch gefertigt.

Onlineworkshops

Schnell, effektiv, informativ und praxisnah

OnlineWorkshops sind die Lösung von THALETEC, schnell, effektiv und zielgerichtet fundiertes Entscheidungswissen in der emaillierten Apparatetechnik zu vermitteln.

OnlineWorkshops führen wir regelmäßig durch. Anmeldeschluss ist jeweils ein Tag vor dem Workshop-Termin.

Hier können Sie sich für den nächstfolgenden Workshop anmelden.

Unsere Produkte

für die chemische und pharmazeutische Industrie weltweit.

THALETEC entwickelt und fertigt alle Arten von Apparaten und Komponenten aus emailliertem Stahl. Für Anwendungen in der chemischen und pharmazeutischen Industrie weltweit.

Emaillierter Stahl ist die erste Wahl, wenn es um höchste chemische Widerstandsfähigkeit und perfekte Sauberkeit geht.

Vertrauen Sie auf die jahrzehntelange Kompetenz von THALETEC bei der Entwicklung und Herstellung innovativer emaillierter Apparate und neuartiger Komponenten und Lösungen.

Anwendungsbereiche

Universell chemisch beständig

Technisch emaillierte Apparate werden vorwiegend in der chemischen und pharmazeutischen Industrie eingesetzt. Hervorragende chemische Beständigkeit der Emaillierung und gute Reinigbarkeit der medienberührten Oberflächen sind der Garant für hochwertige sind hierzu grundlegende Voraussetzungen. Diese werden durch Apparate und Bauteile von THALETEC vollständig erfüllt.

Neben Apparaten und emaillierten Bauteilen liefert THALETEC auch Ersatzteile für Apparate anderer Hersteller.

Dienstleistungen

Jederzeit zu Diensten

Nichts ist so wichtig wie Service! Und der wird bei THALETEC großgeschrieben. Ein umfassendes Angebot an Service und Dienstleistungen ergänzt das Produktionsprogramm von THALETEC. Eine Vielzahl von Servicetechnikern und Monteuren stehen jederzeit bereit, wenn es um Wartung, Instandhaltung und Instandsetzung Ihrer emaillierten Apparate geht.

Ein umfangreiches Programm an emaillierten Ersatzteilen, Verschleißteilen und Verbrauchsmaterialien stehen ebenso jederzeit zur Verfügung.

THALETEC als Arbeitgeber

THALETEC ist ein Traditionsunternehmen mit hohem Innovationspotential.

Wir bieten anspruchsvolle Arbeitsplätze in einer attraktiven und gut zu erreichenden Region in den Neuen Bundesländern.

Um mit diesem Kapital im Markt zu wachsen, bauen wir auf engagierte und qualifizierte Mitarbeiterinnen und Mitarbeiter. Erst die Kombination von hochwertiger Technologie und hochmotiviertem Personal garantiert die Fertigung auf höchstem Niveau.

Mit ca. 180 Mitarbeiterinnen und Mitarbeitern ist THALETEC erfolgreich. Das positive Betriebsklima ist geprägt durch Respekt, Fairness und Identifikation mit dem Unternehmen.